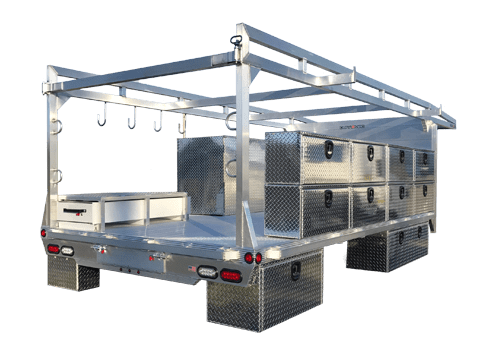

Aluminum Truck Beds

F3 Manufacturing, which includes aluminum truck rack company Magnum Manufacturing as well as truck and van bodies manufacturer DuraMag, offers a large variety of aluminum truck beds to meet your business’s needs. We have truck beds for everyday hauling, heavy duty loads, and everything in between. From landscaping and construction use, to platform and haulers, we have a truck bed designed specifically for your application. Our aluminum beds are thoroughly tested to ensure they are will outlast and out perform any other truck bed on the market.

The History of Magnum Manufacturing and DuraMag

F3 MFG has been involved in the custom aluminum fabrication industry since 1995, and officially entered the aluminum truck body and accessories industries in 2009, launching Magnum Manufacturing and DuraMag Truck Bodies. After studying the truck rack and truck body markets, we determined there was a huge opportunity to make an impact where other manufacturers were not, by introducing aluminum options in these industries. Simply put, it was clear that aluminum racks and truck bodies were far superior to the existing steel options available.

Our experience in the aluminum recreational trailer industry prior to 2009 proved we could make a major change in truck bodies. In fact, we drove the market change for Aluminum trailers in the recreational trailer business by creating a new way to develop and market Aluminum trailers at steel prices. Our team created the largest manufacturer of Aluminum recreational trailers in North America. We knew F3 MFG could also transform the truck rack and truck and van bodies markets, and that’s exactly what we’ve done.

Quality Sets Us Apart

We use only quality materials when manufacturing our truck racks and bodies, and we’re confident that when maintained, our beds will never rust; regardless if it’s a medium duty bed, landscape bed or dump body. We use high quality box tube extrusion and 6005 T6 extrusion for superior strength and durability. The floors of our truck beds are made from interlocking planking giving a rugged appearance coupled with superior durability. Furthermore, the lights of our truck beds are wired LED lights that are rubber mounted in our box tube extrusion. Our wire harnesses also use heat sink butt connectors. Nothing is exposed to the weather and everything important is always protected.

Furthermore, our lead times for designing and manufacturing your new product, is incredibly short. Our experienced designers can create custom van and truck bodies to dealer specs faster than the competition. We pride ourselves on the level of precision and expertise that is put into our standard, HD, heavy duty and custom beds and bodies. We can build aluminum truck beds and bodies for Dodge, Ford, GMC, Chevrolet, Toyota trucks and more.

For many of our aluminum truck bed models there are also options for various heavy duty sill lengths and upgrades as well as light bars, depending on the specs of your truck and what you need. To make working with us even easier for you, we can either weld on your sills according to dealer specs or ship them to you separately for you to position as you prefer.

We take pride in our work and we look forward to new challenges. We can provide a quote for any custom bed or body that you dream up and look forward to tackling the task. None of our truck beds were designed on a white-board. We build them and tear them apart then rebuild them until we have created the best bed for longevity, performance and durability. Whenever we build a bed we have the working man in mind and put ourselves in your shoes.

The Benefits of Aluminum

We work strictly with aluminum and never with steel, because we know it’s a superior option for our customers. There are numerous benefits to aluminum truck bodies and beds, including cost savings for our customers, increased efficiencies across a business and environmental benefits as well.

Did You Know? Get the real facts about aluminum:

- Aluminum is no longer priced at a premium. DuraMag truck beds and bodies are priced competitively or lower than our steel competitors.

- Because our truck bodies weigh up to 40% less than steel, our competitors can haul more payload in every trip. This equates to less drivers needed, and a serious time savings.

- Lighter truck bodies and beds means less fuel needed every time you fill up at the tank.

- Another benefit to your team is that aluminum bodies are typically a more comfortable ride for your drivers.

- They’re more environmentally friendly as they produce fewer greenhouse gases than other metals.

- An Aluminum body lasts longer than a steel body. Why settle for a steel truck body that will only last the span of one single company truck? Aluminum bodies won’t deteriorate, so they’re able to be moved to a second truck when the initial truck wears out over time.

- Aluminum bodies are easier to perform maintenance on, because the metal is much easier to cut than steel.

- With aluminum, there is no more scraping old paint from a steel body before any welding or work can be done!

- Aluminum truck bodies also do not rust over time like steel bodies do. They appear new and polished, year after year when they’re maintained.

- Trading in your truck? In the event you leave your aluminum body or bed on, you’ll increase your truck’s trade-in value. On the other hand, rusted steel bodies will generally deduct value from your trade-in.

Summary

At Magnum Manufacturing and DuraMag Truck and Van Bodies, our goal is to continue to shape the truck accessories and bodies markets by showing consumers that opting for aluminum means cost savings, increased fuel efficiencies, less maintenance on rust repair and repaint, and significantly higher payloads among numerous additional benefits. Most importantly, an aluminum product is a more professional look for your company.